Selecting and installing a thumb grab bucket for excavator. Here’s a breakdown of what we need to know: Understanding Your Machine’s Requirements Highlighting the importance of accurate measurements. For instance, when requesting a thumb attachment, one crucial measurement is “Measurement A,” which determines the length required from the pin on the dipper arm to the tip of the bucket. This measurement ensures the thumb fits precisely and operates effectively. Additionally, for hydraulic thumbs, another essential measurement is taken 100 millimeters above the arm to assess available space. This measurement helps determine the appropriate size and type of thumb that can be…

Understanding Crusher Buckets Crusher buckets are specialized attachments designed to break down various materials such as concrete, bricks, and rocks. They find extensive use in industries such as quarrying, mining, and demolition, where substantial amounts of debris and waste need efficient disposal and recycling. Typically, a crusher bucket features a standard bucket design fitted with a jaw crusher mechanism. Once the material is crushed to a manageable size, it exits through the bottom of the bucket. Advantages of Using Crusher Buckets One of the primary advantages of utilizing crusher buckets is time efficiency. Operators no longer need to wait for…

The primary advantage of a rotary screening bucket lies in its versatility and cost-effectiveness. By integrating directly into existing machinery, it reduces the need for standalone screening operations, thereby optimizing both time and resources. This integration is facilitated through robust construction and compatibility with a wide range of excavator sizes and brands. Moreover, the design ensures operational simplicity. The rotary motion of the drum, powered by the host vehicle, initiates the screening process. As material is fed into the bucket, larger particles are retained within the drum while finer particles fall through the screens. This mechanized separation not only accelerates…

Understanding Tilt Hitches and Tilt Couplers Tilt hitches and tilt couplers are hydraulic attachments designed to facilitate the rotation of attachments mounted to excavators. This rotational capability enables operators to adjust the angle of attached buckets, grapples, and other tools horizontally, thus improving maneuverability and operational versatility. By integrating hydraulic systems, these attachments offer seamless control over the orientation of tools, enhancing productivity in tasks such as grading, trenching, and material handling. Variety and Application The market for tilt hitches and tilt couplers caters to a spectrum of excavator sizes, ranging from mini excavators to larger models such as 5-tonne…

Quick hitches and quick couplers play a pivotal role in modern excavation practices, offering efficiency and versatility in equipment operation. These devices facilitate rapid attachment changes, enabling operators to swiftly transition between different tools and tasks. This article provides a detailed examination of the diverse array of quick hitches available for excavators and diggers, emphasizing their functionality, compatibility with equipment specifications, and market dynamics. Diverse Range of Products The market for quick hitches and couplers exhibits a broad spectrum of offerings tailored to various excavation equipment types and sizes. Keywords such as “excavator quick hitch,” “mini digger quick hitch,” and…

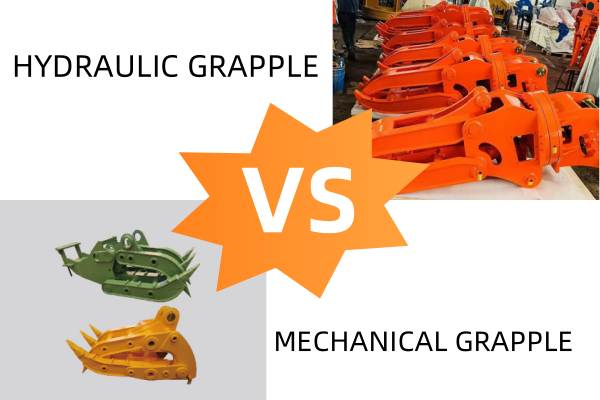

Mechanical and hydraulic grapples are both used for material handling but differ significantly in their operation and application: Key Differences: Common HYDRAULIC GRAPPLE: Wood Grapple,Orange Peel Grab,Stone Grapple Frontier AV20E Hydraulic Root Grapple VS Frontier MG20F Mechanical Grapple Begins by explaining the fundamental operational variances between the two types of grapples. The AV20E Hydraulic Root Grapple utilizes a third function hydraulic valve kit, enabling precise control over the upper jaw’s movement. In contrast, the MG20F Mechanical Grapple relies on gravitational force to open its lower jaw and standard loader bucket cylinders for upper jaw control. Both grapples are put through…